working principles of ne crusher

2021-09-08T09:09:47+00:00

Working Principle of Crushers 911 Metallurgist

2016年2月17日 The crusher head is at the moment in the closeside position Crusher Working Principle As the head recedes on its opening 2021年11月9日 Working principle of crushers pdf working principle of crushers pdf operation and maintenance of crusher house for received, then the coal is sent directly principle operation of ne crusher Crusher MachineThe basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motion That Cone crusher basics in 4 minutes rockprocessing

Working Principle of 4 Commonly Used Crushers miningpedia

2022年1月14日 Working Principle When the cone crusher is working, the motor drives the eccentric sleeve to rotate through the transmission device The moving cone rotates and 2021年8月15日 This work opens with a brief review of the mechanical principles of cone crushers Then, in the following sections, works available in the cone crusher literature, A review of modeling and control strategies for cone crushers 2022年12月12日 The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as well With the higher What Is the Cone Crusher Working Principle?

Understanding the Cone Crusher Working

2023年2月21日 In this comprehensive guide, we'll explain the working principle of a cone crusher, its components, maintenance tips, benefits, and offer practical advice on how to choose the right cone crusher for your 2023年7月31日 What are the Working Principles of a Cone Crusher? The cone crusher operates based on the principles of compressive crushing The crushing process can be How Does A Cone Crusher Work: Understanding The Working principle of gyratory crusher for breaking lumpy ore pressed between a fixed jaw and rotating conical head 13312 Secondary Crusher The secondary crusher is mainly Crusher an overview ScienceDirect Topics

Crusher an overview ScienceDirect Topics

The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw 2023年7月31日 The cone crusher has a high reduction ratio, ensuring efficient material crushing Discharge: This is the final stage of the crushing process When the material is crushed into the preferred size, it exits the cone crusher through an opening at the bottom The entrance is located between the mantle and the bowl linerHow Does A Cone Crusher Work: Understanding The 2021年11月9日 Mobile Rock Stone Jaw Crusher Pe250*400,Portable Mini The working principle of jaw crusher is very simple The whole crushing process rely on the relative motion of the two jaw platesOne of the jaw plates stay still while the other move against itAnd with the movement, the materials between the two plates would be crushed into working principle of mobile ne mill Crusher Machine

Types of Crushers: What You Need to Know Machinery

Crusher machines come in a wide variety of sizes and capacities, from small jaw crushers that cost the same as a new truck to extra large cone crushers that cost millions of dollars Impact crushers have a very similar working principle except instead of the rotating parts hitting the material like a hammer, they instead throw the material 2021年8月11日 This work opens with a brief review of the mechanical principles of cone crushers Then, in the following sections, works available in the cone crusher literature, ranging from 1972 to 2020, are categorized with respect to the model structure and control strategy implementation Remarks about the most important contributions of each work A review of modeling and control strategies for cone 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics

Crusher an overview ScienceDirect Topics

A hammer crusher is suitable for midhard and light erosive materials such as coal, salt, chalk, gypsum, limestone, etc 9321 Coal Hammer Crusher Operating Principles Hammer mills are primarily steel drums that contain a vertical or horizontal crossshaped rotor mounted with pivoting hammers that can freely swing on either end of the cross2 天之前 Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers Cone crushers have traditionally been used as secondary and sometimes tertiary crushing How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment2022年1月14日 Working Principle When the cone crusher is working, the motor drives the eccentric sleeve to rotate through the transmission device The moving cone rotates and swings under the forced movement of the eccentric shaft sleeve The section of the moving cone close to the static cone becomes the crushing cavity The material is crushed by Working Principle of 4 Commonly Used Crushers miningpedia

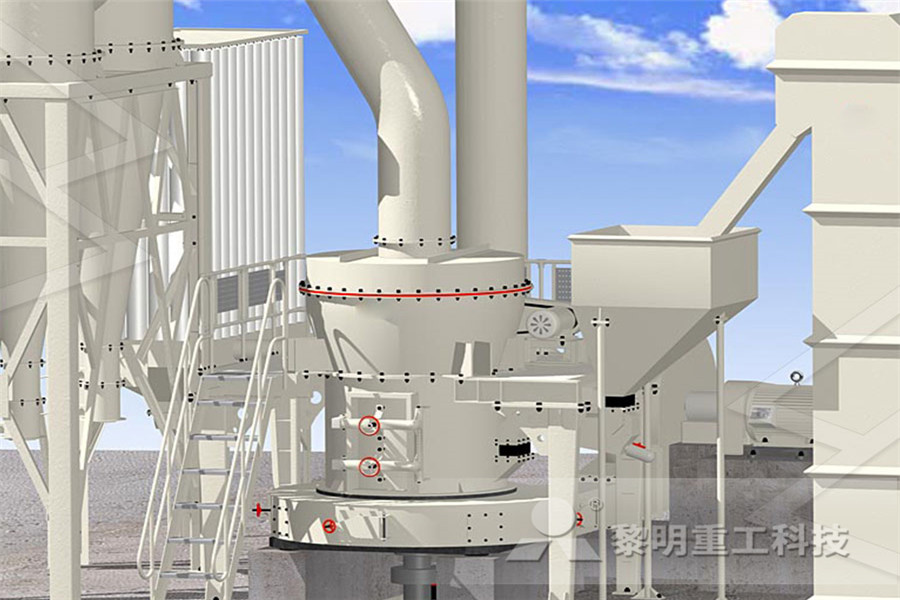

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically or hydraulically actuated) Cone Crusher Components Top Shell Spider Cap Assembly The feed is fed by conveyors to a feed 2021年11月18日 Several tests are normally used to analyze the resistance of rocks and ores to breakage in the mining/aggregate industries Some of these tests yield results that serve as basis for either simple mathematical expressions or comprehensive models, whereas others are essentially only used to classify a rock or ore in comparison with Simulating breakage tests using the discrete element 2023年11月1日 The Smooth Roll Crusher plays a key role in bulk raw materials preparation, processing clays, coal fines, coke breeze and gypsum waste Smooth roll crushers are used to particularly suitable for medium Rolls Crushers Smooth Roll Crushers, Wroking,

How Does a Jaw Crusher Work? Industrial Technology

2023年1月5日 The jaw crusher works by using a moving jaw and a fixed jaw to crush and grind the rocks The material is fed into the jaw crusher by a vibrating feeder, and then it is crushed between the two jaws The jaw crusher is made up of several parts, including a fixed jaw, a moving jaw, and a toggle plate The fixed jaw is mounted to the frame of the 2021年11月9日 Working principle of nail making machine Apr 28, 2021 The punching motion on the nail making machine is driven by the rotation of the main shaft (eccentric shaft) to drive the connecting rod and the punch to form a reciprocating motion, thereby implementing the punching motion The clamping movement is the repeated pressure of Principle and Working Of ne Making Machine Crusher 2015年5月13日 The basic operating principle of a cone crusher is shown in Figure 4 The properties, ie size distribution and quality parameters, of the product leaving the crusher are a result of the(PDF) Cone Crusher Performance ResearchGate

Jaw Crusher Working Principle Applications Benefits MC

2 A jaw crusher is a popular crushing machine used in the mining, construction, and recycling industries It is commonly used in applications where the primary objective is to reduce large rocks into smaller sized rocks, gravel, or rock dust This article will explain how a jaw crusher works, its applications, and its benefits2013年4月18日 The hammer crusher has the following characteristics in structure: compact structure, reasonable layout, Working Principles of Hammer Crusher Equipments cnm2386 于 13:16:02 发布 65 收藏 The hammer crusher has the following characteristics Working Principles of Hammer Crusher Equipments CSDN 2016年2月17日 The crusher head is at the moment in the closeside position Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1” Note that the length of line “1″ from concave to openside head position, is the same as that of Working Principle of Crushers 911 Metallurgist

Bucket Elevator Belt Bucket Elevator Chain Bucket Elevator

The bucket elevator produced by our company can be divided into ring chain bucket elevator (TH), plate chain bucket elevator (NE) and belt bucket elevator (TD) according to different traction modes Ring chain bucket elevator is a commonly used lifting machine The TH series elevators using ring chain as the transmission part has a strong 2021年11月1日 Fig 3 illustrates the operating principle and the main components of a cone crusher A cone crusher basically comprises two bellshaped manganese crushing liners placed inside each other The concave is attached to the crusher frame and the mantle to the eccentric main shaft which is swaying around the geometric center point at the Size reduction control in cone crushers ScienceDirect2023年2月28日 The working principle of tertiary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through compression or impact VSI crushers work by throwing the material against a hard surface to produce a cubicalshaped product Cone crushers and roll crushers work by compressing the The Complete Guide to Primary Crushing, Secondary

working principle of ne crusher

working principle of ne crusher T01:11:02+00:00; principle operation of cone crusher principle operation of cone crusher Operation mode of cone crusher 1 The appropriate adjustment of the spring and the elastic tension of the transmission belt 2 Do a good job of lubrication equipment the temperature can not be too high or too low but 2022年2月22日 Jaw Crusher Working Principle A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller Jaw Crusher: Range, Working Principle, Application WORKING PRINCIPLE OF PNEUMATIC CAN CRUSHER The bottle crusher is a screw operated device used for many small operations It is a portable one The screw shaft produces the compression action is the source of energy for this device The compression is allowed through the die in such a way that it produces the blank of a bottle by compressingPNEUMATIC CAN CRUSHER PROJECT REPORT Mechanical

Automatic Double Roll Crusher 知乎

Working Principle Toothed Roll Crusher is worked by making two toothed roll rotate oppositely under the action of two pulleys on two sides of crusher, which driven by one motor or some motors Thus the materials reaching the required size fall and discharged automatically, while the ones larger than two toothed rollers still left to be crushed until 2020年6月3日 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries Inside the crusher, a piece of steel, known as the mantle, rotates eccentricallyA Detailed Overview of Cone Crushers and What You Need working principle of ne crusher T17:11:16+00:00 Cone Crushers Working Principle Dragon Machinery Cone Crushers Working Principle When Cone crusher is working, the motor drives the eccentric bush via bevel pinion gear Mantle core is forced to swing by the eccentric bush, which makes the mantle sometimes close to the concave, working principle of ne crusher sarljlbduisans

How a Laboratory Crusher Works XRF

Laboratory Crusher Working Principle The primary mechanism of conventional laboratory crushers is the jaw crusher, which typically features a fixed plate and a mechanicallyoperated, gyrating plate These are arranged in an angled, funnel shape, with a wider feed opening at the top and a narrow discharge aperture at the bottom Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushingCone crusher basics in 4 minutes rockprocessing2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap How it Works: Crushers, Grinding Mills and Pulverizers

A review of modeling and control strategies for cone crushers

2021年8月15日 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017)The maximum distance between the mantle and concave, on the other \n \n crushers working principle depalenrammers \n Jaw Crusher Working PrincipleJaw crusher is widely used in industrial and mining enterprises,this is because the aircraft structure is relatively simple,and has a large range of modelsJaw crusher is mainly used as the primary crusherIt can be used with mineral processing equipment,gravel ancillary jaw crusher working principle with diagram in mechanical 2021年11月9日 Electrical types of operation 2 WORKING PRINCIPLE The crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is taken from an electrical motor It is designed to use a 3 phase induction motor for the for the cone crushers which are used to crush the rocks China principle operation of ne crusher Crusher Machine

How Impact Crushers Work: A Comprehensive

2023年3月11日 The basic working principle of an impact crusher The fundamental working principle of an impact crusher is fairly straightforward, yet its impact force can be substantial The machine crushes materials 2019年6月6日 This project is mainly about designing and analyzing duo operating can crusher by using the knowledge gained in ENT 348 Mechanical System Design In this project, the analysis done is main focus (PDF) Mechanical System Design ResearchGateworking principles of ne crusher T15:09:58+00:00 Cone Crusher Working Principle Animation Engineering Aug 15, 2012 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel working principles of ne crusher MC World

Understanding the Cone Crusher Working Principle For Right

2023年2月21日 In summary, a cone crusher operates by rotating the mantle and the concave at high speeds, which compresses and breaks down rocks into smaller pieces The gap between the mantle and the concave is used to determine the size of the output material, and the adjusting mechanism is used to control the gap and adjust the size of working principle of a washing machine ppt Page 2 of results for the term 'working principle of a washing machine ppt' CIRCUIT IDEAS WASHING MACHINE CIRCUIT IDEAS SEPTEMBER 2003 ELECTRONICS FOR YOU WASHING MACHINE MOTOR CONTROLLER SC DWIVEDI SANTHOSH VASUDEVAN W ashing machines usually Working Principle Of Washing Machinepdf Crusher Mills, Cone Crusher 2016年8月15日 Major part of hammer crusher is the hammer head, which often works at high speed During the working process, rotors run at a high speed and bring the hammer head to move rapidly From the feeding Working Principle of Cone Crusher Hammer Crusher

working principles of a ne crusher

working principles of a ne crusher T07:05:54+00:00; What Is the Cone Crusher Working Principle? The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as well With the higher production and higher quality, it is becoming more and more popular among construction 2022年12月23日 1、Working principle of heavy hammer crusher: The motor drives the rotor to rotate at high speed in the crushing cavity, and the material is fed into the machine from the upper feeding port and how a stone crusher operates LinkedIn2023年7月31日 The cone crusher has a high reduction ratio, ensuring efficient material crushing Discharge: This is the final stage of the crushing process When the material is crushed into the preferred size, it exits the cone crusher through an opening at the bottom The entrance is located between the mantle and the bowl linerHow Does A Cone Crusher Work: Understanding The

working principle of mobile ne mill Crusher Machine

2021年11月9日 Mobile Rock Stone Jaw Crusher Pe250*400,Portable Mini The working principle of jaw crusher is very simple The whole crushing process rely on the relative motion of the two jaw platesOne of the jaw plates stay still while the other move against itAnd with the movement, the materials between the two plates would be crushed into Crusher machines come in a wide variety of sizes and capacities, from small jaw crushers that cost the same as a new truck to extra large cone crushers that cost millions of dollars Impact crushers have a very similar working principle except instead of the rotating parts hitting the material like a hammer, they instead throw the material Types of Crushers: What You Need to Know Machinery 2021年8月11日 This work opens with a brief review of the mechanical principles of cone crushers Then, in the following sections, works available in the cone crusher literature, ranging from 1972 to 2020, are categorized with respect to the model structure and control strategy implementation Remarks about the most important contributions of each work A review of modeling and control strategies for cone

Crusher an overview ScienceDirect Topics

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The A hammer crusher is suitable for midhard and light erosive materials such as coal, salt, chalk, gypsum, limestone, etc 9321 Coal Hammer Crusher Operating Principles Hammer mills are primarily steel drums that contain a vertical or horizontal crossshaped rotor mounted with pivoting hammers that can freely swing on either end of the crossCrusher an overview ScienceDirect Topics2 天之前 Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers Cone crushers have traditionally been used as secondary and sometimes tertiary crushing How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

Working Principle of 4 Commonly Used Crushers miningpedia

2022年1月14日 Working Principle When the cone crusher is working, the motor drives the eccentric sleeve to rotate through the transmission device The moving cone rotates and swings under the forced movement of the eccentric shaft sleeve The section of the moving cone close to the static cone becomes the crushing cavity The material is crushed by Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically or hydraulically actuated) Cone Crusher Components Top Shell Spider Cap Assembly The feed is fed by conveyors to a feed Cone Crushers (Parts of a Cone Crusher) Explained saVRee2021年11月18日 Several tests are normally used to analyze the resistance of rocks and ores to breakage in the mining/aggregate industries Some of these tests yield results that serve as basis for either simple mathematical expressions or comprehensive models, whereas others are essentially only used to classify a rock or ore in comparison with Simulating breakage tests using the discrete element