process process of iron ore screening

2020-08-10T04:08:13+00:00

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents 2022年1月1日 Iron ore crushing and screening Iron ore is one of the main raw materials to make steel About 98% of the mined iron ore is used to make steel either by the blast Comminution and classification technologies of iron ore2017年3月3日 Sieving is a process of separation of the ore material into multiple grades by particle size [1] The screen is a vibrating mining (PDF) ORE SEPARATION BY SCREENING

Life cycle assessment of iron ore mining and processing

2015年1月1日 Screening is an important step for dry beneficiation of iron ore Crushing and screening is typically the first step of iron ore beneficiation processes In most ores, 2022年3月18日 The roller screening process is an important step in the iron ore pellets production This step is intrinsically linked to the balling production and the induration Impact of key parameters on the iron ore pellets roller screening 2022年6月10日 The roller screening process is an important step in the iron ore pellets production This step is intrinsically linked to the balling production and the induration machine Improvements to(PDF) Impact of key parameters on the iron ore

Impact of key parameters on the iron ore pellets roller

The roller screening process is an important step in the iron ore pellets production This step is intrinsically linked to the balling production and the induration machine2017年1月1日 PDF Effective technology for a complex wasteless processing of the iron ores has been designed and includes three main components (plats): comminution (PDF) Effective Processing of the Iron Ores ResearchGate2023年11月8日 The biomass pyrolysis process and iron ore reducing process are two reaction stages in this process: (1) The biomass pyrolysis process The degradation Sustainability Free FullText Utilization of Waste Straw

(PDF) Life cycle assessment of iron ore mining and

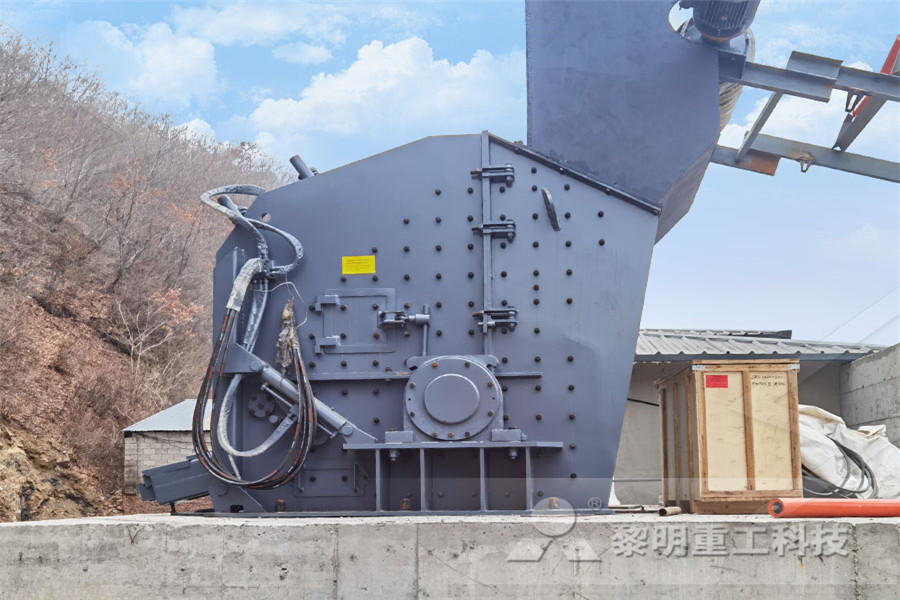

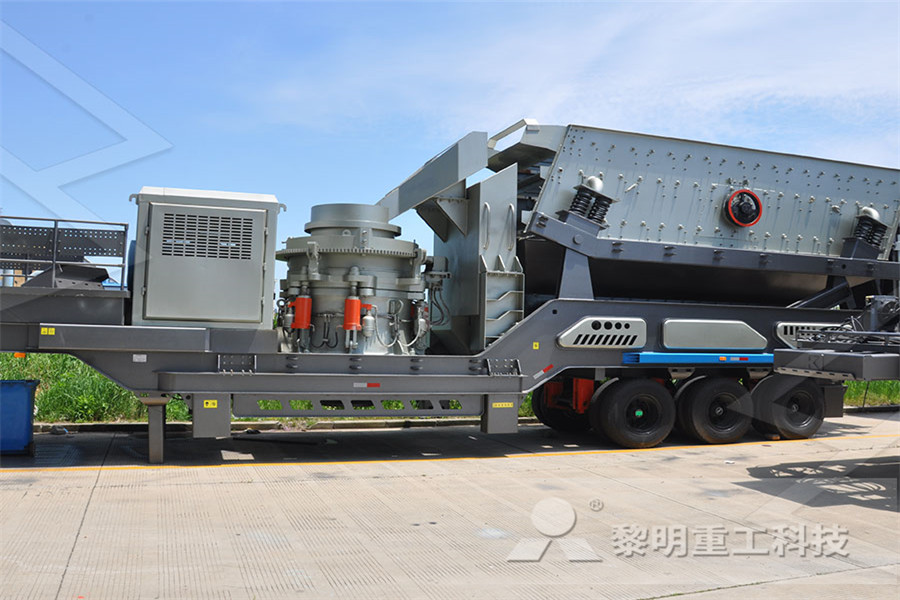

2015年12月31日 Terry Norgate Abstract and Figures Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in2019年11月4日 It has been the dominant iron ore mined in Australia since the early 1960s Approximately 96% of Australia's iron ore exports are highgrade hematite, the bulk of which has been mined from deposits in the Iron Ore Geoscience Australia2021年6月25日 The crushing process generally includes crushing, prescreening, and inspection screening steps, and if necessary, it also includes ore washing or predressing operations LinkedIn Asa GuoCOMMON IRON ORE CRUSHING AND

Iron Ore production in the Pilbara Rio Tinto

2023年6月2日 Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the process2016年10月28日 Abstract and Figures Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slagforming elements and coke The purpose of sintering is to obtain a product (PDF) Iron Ore Sintering: Raw Materials and Granulation2022年8月3日 Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing Generally, materials with a size of 10mm or less can be screened for dry selection After screening, materials with a size of 1040mm enter the fine crusher for fine crushingIron ore crushing and screening process Ultrafine

Metals Free FullText Impact of Iron Ore PreReduction

2023年3月10日 To counteract the rising greenhouse gas emissions, mainly CO2, the European steel industry needs to restructure the current process route for steel production Globally, the blast furnace and the subsequent basic oxygen furnace are used in 73% of crude steel production, with a CO2 footprint of roughly 18 t CO2 per ton of produced 2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface (s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”Ore, Rock Aggregate Screening (Complete Guide) 911 2015年1月27日 Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept, Iron Unit Div, Engineering Business *2 Plant Engineering Dept, Iron Unit Div, Engineering Business *3 Ironmaking Dept, Beneficiation Plants and Pelletizing Plants for Utilizing

The production of pig iron from crushing plant waste using hot

2018年3月1日 The second procedure prepared composite pellet as shown in Fig 2The palletizing process is one of the most important steps to furnish agglomerates of high quality with additional benefits of recycling the ultra fines within the steelmaking industry [5]Composite pellet was made from raw material particle size of −8 + 100 mesh with 2015年12月31日 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment of the mining and mineral processing of iron ore in Australia was carried out in this chapter using (PDF) Life cycle assessment of iron ore mining and processing2014年4月3日 Fig 3 Types of processing ores The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore The wet process consists of multistage crushing followed by Beneficiation of Iron Ores – IspatGuru

Thermodynamic Analysis of Iron Ore Sintering Process Based

2020年11月16日 The sinter process of iron ore with biomass carbon instead of coke breeze as fuel was investigated via thermodynamic analysis in this paper through a comparison of sinter composition indexes, metallurgical properties, and pollutant emissions Straw charcoal was used in this paper, and its replacement does not adversely affect the 2022年6月10日 The roller screening process is an important step in the iron ore pellets production This step is intrinsically linked to the balling production and the induration machine Improvements to the (PDF) Impact of key parameters on the iron ore 2021年2月17日 COMMON IRON ORE CRUSHING AND SCREENING PROCESS Jun 25, 2021 Gold Sulfide Beneficiation Process, Sulfide Gold Beneficiation Equipment May 3, 2021 HEMATITE BENEFICIATION PROCESS, HEMATITE Overview of Ore Washing in the Mineral Processing Industry

Pelletization of iron ores and the type of wear liners used in

2016年12月10日 Engineering Now a days about 60% of iron ore converted to fines during mining, handling and transporting so pellet is a process of utilizing iron ore fines up to size of 015 microns i investigate its process,equipment used in process, wear and other problems in them and its future scope G Gulshan Kumar Singh2022年7月22日 After the heating process, the heated base mix will converted into a semi liquid cake Using a sinter breaker machine the cake is break into small pellets Finally these iron ore pellets under goes cooling in the cooling tower Later the iron ore pellets goes with the sinter screeners for screening process The unsized iron oreOPTIMIZATION OF IRON ORE PELLETS PRODUCTION IN 2013年1月1日 The two step process uses a cyclone, where the fine ore is prereduced and melted, and an iron bath reactor where the ore is finally reduced Contrary to the conventional HIsmelt process, the pyrolysis of the coal takes place outside the process in a reactor, which uses the heat generated by degassing the coal ( Luengen et al, 2011b )Coal use in iron and steel metallurgy ScienceDirect

Dry beneficiation of iron ore Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 635 % iron content For fine ore beneficiation, wet processes are used Capacity at the Minas Rio is to be increased from 265 Mta capacity to 28 Mta in the forthcoming years2021年12月2日 Purchase Iron Ore 2nd Edition Print Book EBook ISBN 65, 72 Books; 82 Iron ore crushing and screening 153 Evaluation of iron ore for the sintering process 154 Recent developments in iron ore sintering 155 Conclusions AcknowledgmentsIron Ore 2nd Edition Elsevier2017年2月16日 Abstract Sintering is a process of agglomeration of iron ore fines, fluxes, recycled products, slagforming elements and coke with the purpose of achieving an agglomerated product with the (PDF) Iron Ore Sintering: Environment Automatic and

(PDF) Thermodynamic Analysis of Iron Ore

2020年11月16日 include the drum index, screening index, and abrasion resistance index Al2O3 and SiO2, on the solidstate formation in the sintering process of iron ore fines were investigated quantitatively impact on the iron ore pelletizing process 3 Screening efficiency definition It is important to set the understanding of the screening efficiency in a roller screening process For that, we must consider the efficiency of a specific equipment to retain the good size pellets in the final product, and the capacity toImpact of key parameters on the iron ore pellets roller 2022年12月15日 Another promising solution is the Outotec Circored™ process, which is a 100% hydrogenbased process for the direct reduction of iron ore fines” This reduction process, when coupled with our DRI Smelting technology, has high potential to reduce the carbon footprint of the traditional blast furnace steelmaking route Outotec supports Rio Tinto with breakthrough

Iron Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 The former mainly selects magnetite ore, and the latter is mainly used for sorting hematite, mixed iron ore and weak magnetic ore 62 Magnetic separation – cation reverse flotation process The grade of iron concentrate increased from 6555% to 3889%, the silica content decreased from 831% to 390%, and the iron recovery rate was over 2018年9月18日 Iron ore is the basic raw material for iron and steel making India is among the leading producers of iron ore in the world and produces about 150 million tons per annum (U S [])The total reserves of iron ore in India is around 285 billion tons, of this hematite ore is considered to be the most important iron ore because of its high grade Characterization and Beneficiation of Dry Iron Ore SpringerIron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements Our polyurethane and rubber iron ore screening Iron Ore Screening Multotec

Mathematical Simulation of Iron Ore Fines Sintering Process

2022年12月11日 The fuel segregation distribution sintering process, with a high fuel dosage in upper layer and a low fuel dosage in bottom layer of the sintering bed, was studied to handle uneven heat distribution problems in the conventional iron ore sintering process A mathematical simulation method was adopted to contrastively study the fuel 2022年1月14日 The reduced iron ore fines are discharged through pressure reducing device and enter an insulated tank from where direct reduced iron is discharged at 650oC It is compacted in the hot condition in a briquetting machine into briquettes for further use HIB Process: The full form of this process is High Iron Briquette processChapter 1 Review of Sponge Iron Making Process 2019年4月15日 Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate In this paper, iron recovery from IOTs was studied at different points during a process involving preconcentration followed by direct reduction and magnetic separation Then, slagtailing concrete composite admixtures Minerals Free FullText Recovering Iron from Iron Ore

Carbon Impact Mitigation of the Iron Ore Direct Reduction Process

2020年2月11日 The steel industry is known to have one of the highest environmental impacts on the industrial sector, especially in terms of CO2 emissions The socalled direct reduction route, which makes use of reformed natural gas along with top gas recycling to reduce iron oxide pellets with H2 and CO, is responsible for lower CO2 emissions than 2021年7月2日 The studies on removal of impurities by WHIMS indicated reduction in iron oxide content and in this process, magnetic intensity, grain size and ore characteristics of laterite play an important role The tests indicated that laterite can be blend with metallurgical grade bauxite for alumina productionBeneficiation of LowGrade Bauxite: A Case Study of2021年11月3日 The sintering process is a thermal agglomeration process, and it is accompanied by chemical reactions In this process, a mixture of iron ore fines, flux, and coal particles is heated to about 1300 °C–1480 Minerals Free FullText A Short Review of the

Optimization of the Iron Ore Direct Reduction

2018年6月27日 Iron ore direct reduction is an attractive alternative steelmaking process in the context of greenhouse gas mitigation To simulate the process and explore possible optimization, we developed a 2013年11月5日 ironmaking process alternatives screening study volume i: summary report slurry pipeline concentrate slab shipping iron ore mine ore beneficiation concentrator slurry receiving, dewatering pellet plant natural gas natural gas production direct reduction plants pellet stockpile dri eaf melting electric power (50% from coal, 50% from ng) slab Ironmaking Alternatives Screening Department of EnergyIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine

Research Progress of Intelligent Ore Blending Model

2023年2月13日 The iron and steel industry has made an important contribution to China’s economic development, and sinter accounts for 70–80% of the blast furnace feed charge However, the average grade of domestic iron ore is low, and imported iron ore is easily affected by transportation and price The intelligent ore blending model with an intelligent 2021年2月9日 Mining waste may contain potential minerals that can act as essential feedstock for longterm carbon sequestration through a mineral carbonation process This study attempts to identify the mineralogical and chemical composition of iron ore mining waste alongside the effects of particle size, temperature, and pH on carbonation Influencing Factors of the Mineral Carbonation Process of Iron Ore 2022年10月2日 Iron ore concentrate is an output product from processed iron ores that have been milled (crush, grind, magnetic separation, flotation) to separate deleterious elements and produce a highquality product Sintering and pelletizing are economic and widely used agglomeration processes to prepare iron ore fines/iron concentrate for Iron Concentrate Particles MDPI

Mathematical Simulation of Iron Ore Fines Sintering Process

The fuel segregation distribution sintering process, with a high fuel dosage in upper layer and a low fuel dosage in bottom layer of the sintering bed, was studied to handle uneven heat distribution problems in the conventional iron ore sintering process A mathematical simulation method was adopted to contrastively study the fuel segregation distribution 2023年2月15日 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roastingHow to Extract Iron from Hematite: Methods and Plants2019年11月4日 It has been the dominant iron ore mined in Australia since the early 1960s Approximately 96% of Australia's iron ore exports are highgrade hematite, the bulk of which has been mined from deposits in the Iron Ore Geoscience Australia

COMMON IRON ORE CRUSHING AND

2021年6月25日 The crushing process generally includes crushing, prescreening, and inspection screening steps, and if necessary, it also includes ore washing or predressing operations LinkedIn Asa Guo2023年6月2日 Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the processIron Ore production in the Pilbara Rio Tinto2016年10月28日 Abstract and Figures Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slagforming elements and coke The purpose of sintering is to obtain a product (PDF) Iron Ore Sintering: Raw Materials and Granulation

Iron ore crushing and screening process Ultrafine

2022年8月3日 The iron ore processing and production process mainly includes three processes: crushing, grinding and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable for highhardness iron ore crushing and can complete the work of ore crushing and partial dissociation, thereby improving the 2023年3月10日 To counteract the rising greenhouse gas emissions, mainly CO2, the European steel industry needs to restructure the current process route for steel production Globally, the blast furnace and the subsequent basic oxygen furnace are used in 73% of crude steel production, with a CO2 footprint of roughly 18 t CO2 per ton of produced Metals Free FullText Impact of Iron Ore PreReduction 2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface (s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”Ore, Rock Aggregate Screening (Complete Guide) 911

Beneficiation Plants and Pelletizing Plants for Utilizing

2015年1月27日 Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept, Iron Unit Div, Engineering Business *2 Plant Engineering Dept, Iron Unit Div, Engineering Business *3 Ironmaking Dept, 2018年3月1日 The second procedure prepared composite pellet as shown in Fig 2The palletizing process is one of the most important steps to furnish agglomerates of high quality with additional benefits of recycling the ultra fines within the steelmaking industry [5]Composite pellet was made from raw material particle size of −8 + 100 mesh with The production of pig iron from crushing plant waste using hot 2015年12月31日 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment of the mining and mineral processing of iron ore in Australia was carried out in this chapter using (PDF) Life cycle assessment of iron ore mining and processing